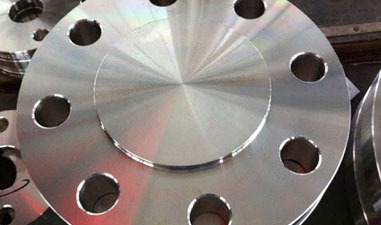

Nascent Pipe & Tubes are proud manufacturers, suppliers, exporters, and stockists of Stainless Steel 321 Flanges. Stainless Steel 321 Flanges are manufactured from a titanium-stabilized chromium-nickel alloy that gives them serviceability and resistance to most forms of corrosion.

The alloy basically consists of 17% chromium, 9% nickel, along with carbon, silicon, manganese, phosphorus, sulfur, nitrogen, titanium, and iron. Nascent Pipe & Tubes is one of the leading manufacturers, suppliers, exporters, and stockists of Stainless Steel 321 Flanges, which are available to clients in a variety of sizes, shapes, and standards.

Stainless Steel 321 Flanges Manufacturers, Stainless Steel 321 Flanges Suppliers, Stainless Steel 321 Flanges Stockists, Stainless Steel 321 Flanges Exporters

Stainless Steel 321 Flanges Manufacturers in India, Stainless Steel 321 Flanges Suppliers in India, Stainless Steel 321 Flanges Stockists in India, Stainless Steel 321 Flanges Exporters in India

This material has high mechanical properties: the yield strength is 30ksi, and the minimum tensile strength is 75ksi. its Brinell hardness rating is 217, a testimony to the strength of this material. The flanges are fabricated according to several standards, which include ANSI, B, ASA, and APA; they are offered in nominal bore sizes from ½ inch up to 48 inches.

the Stainless Steel 321 Blind Flange is majorly used to close the ends of pipes. All these blind flanges can be availed in customized form as per requirements. The material falls under high-pressure material with class ratings falling between 150 classes to 2500 classes. Besides, the Stainless Steel F321 Forged Flange is also used at high-temperature applications due to its excellent corrosion resistance properties which are better than grades like 304, 316 and 310.

These Stainless Steel UNS S32100 Pipe Flanges find applications in industries associated with petrochemicals, food processing, marine environments, and structural. Nascent Pipe & Tubes puts forth a complete range of flanges to fit different requirements of projects, including ANSI B16.5 Stainless Steel 321 Slip On Flanges. Feel free to contact us with further queries on the products we offer and their prices.

Stainless Steel 321 Flanges Manufacturers in Mumbai, Stainless Steel 321 Flanges Suppliers in Mumbai, Stainless Steel 321 Flanges Stockists in Mumbai, Stainless Steel 321 Flanges Exporters in Mumbai

Specifications For Stainless Steel 321 Flanges

| Standards | GOST Flange, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092, BS, BS4504, BS 10, EN-1092, DIN, ANSI, ASME, DIN, MSS S44, ISO70051, ANSI/ASME B16.5, ASME/ANSI B16.5/16.36/16.47A/16.47B, B16.47 Series A & B, B16.48, EN |

|---|---|

| Pressure Rating ANSI | Class 1500, Class 150, Class 900, Class 2500, Class 300, Class 600, |

| Pressure Calculation in DIN | 10Bar, 16Bar, 25Bar, 40Bar, 6Bar, / PN16, PN64, PN40, PN25, PN10, PN6 |

| JIS | 16 K, 20 K, 5K, 10 K, 40 K, 63 K, 30 K, |

| UNI | 10Bar 16Bar 6Bar 25Bar 40Bar |

| EN | 6Bar 25Bar 40Bar 10Bar 16Bar |

| Most common Types | Threaded / Screwed / Forged / Plate |

| Production technique |

|

| Shapes and Types we produce | Large Male-Female (LMF), Ring Type Joint (RTJ), Flat Face (FF), Small Tongue, Small Male-Female (SMF),Raised Face (RF), Large Tongue & Groove, Groove, Lap-Joint Face (LJF) |

| Test | Direct-reading Spectrograph, Magnetic particle detector, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector |

| Equipment | Pushing Machine, Press machine, Bending machine, Sand-blasting machine, electric bevelling machine etc |

Chemical Composition of Stainless Steel 321 Flanges

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| SS 321 | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 16.00 - 18.00 | 2.00 - 3.00 | 10.00 - 14.00 | 68.89 min |

Mechanical Properties of Stainless Steel 321 Flanges

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1399 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Our Export

Domestic Area

| Mumbai | Ahmedabad | Bhopal | Bikaner | Pune |

| Delhi | Chennai | Visakhapatnam | Mangalore | Nagpur |

| Bangalore | Kolkata | Siliguri | Assam | Indore |

| Hyderabad | Surat | Nashik | Cochin | Thane |

| Faridabad | Rajkot | Aurangabad | Bhavnagar | Ranchi |

| Coimbatore | Mysore | Salem | Tirupur | Bikaner |

| Raipur | Bhubaneswar | Bhilai | Ankleshwar | Bhiwandi |

| Vadodra | Kochi |